Call us Now!

(888) 367-3011(888) 367-3011

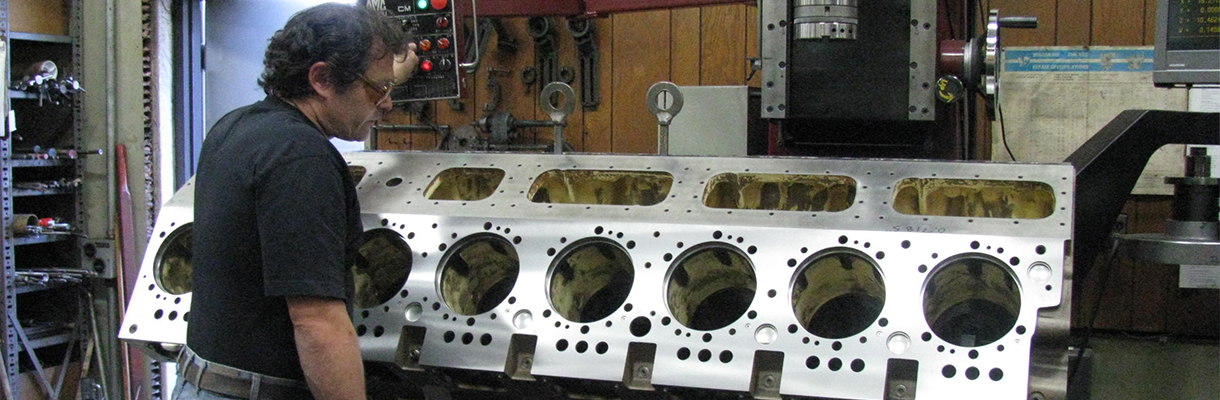

Cylinder Block Rebuilding

All cylinder blocks are cleaned to remove greases, oils and paint. All freeze and oil galley plugs are removed as well as cam bearings. All blocks are then magnafluxed to inspect for casting flaws and cracks. We then machine blocks according to the condition of the block. We will bore and hone the cylinders for oversize pistons or install repair sleeves into the block. We also remachine counterbores for proper liner protrusion. Lower repair bushings are installed where erosion has occurred. All blocks are resurfaced concentric with the lower bores and deck height is measured accurately. The main bearing bore is line honed or line bored. Thrust surfaces are repaired. Loose main caps are tightened. All blocks are then final cleaned to remove machining debris. New cam bearings are installed (line bored when necessary) and freeze and oil plugs are installed. All blocks are then wrapped to maintain cleanliness until the block is delivered to the customer.

Email us at [email protected]